3D printing is an evolving technology that will play an important role in the diagnosis and treatment of dentistry and orthodontics. It is known as the production of a 3D physical object (prototype) using CT and CBCT data and preparing virtual models with the help of computer technology. It is used in the field of oral and maxillofacial surgery, traumatology, osteotomy, placement of osteointegrated implants, and treatment of facial defects.

Three of the 3D printers that are mostly used in dentistry:

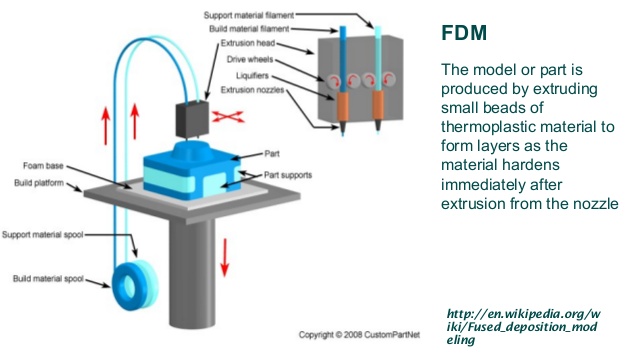

Fused deposition modeling (FDM)

Stereolithography (SLA)

Selective laser sintering (SLS)

FDM 3D printer FDM:

is short for Fused Deposition Modeling. Some references refer to it as FFF, which means Fused Filament Fabrication, which is the concept of melting filament strands (printer consumables) for three-dimensional construction of an object. The FDM method is one of the 3D printing technologies or additive manufacturing. The material used in FDM 3D printers is PLA or ABS filament, which is made of thermoplastic material. These filaments themselves are available in the market in different types such as metal design, wood design, transparent, shiny, etc., which only give a different appearance to the object, and the main composition is the same plastic. The color of the filaments and their appearance are quite diverse. Most FDM 3D printers use two standard sizes of filament: 1.75 or 3 mm diameter. (meaning the diameter of the string in each one kilogram roll). Of course, some 3D printer brands also produce special filaments with different diameters, for example 2mm, which are less acceptable. In Iran, the most common diameter standard is 1.75, which is compatible with all types of models in the country's market and has a lower price than 3 mm. The maximum resolution of the FDM printer is 20 microns (accuracy of 100 to 200 microns is acceptable). Pay attention that with the increase of printing accuracy, the amount of material consumption and construction time increases. In FDM 3D printer technology, there is a wide range of choices: from inexpensive but high-quality desktop 3D printers to large-sized industrial 3D printers. The consumable material or filament is also not very expensive. These features have made the FDM printer the first choice of all home builders and industrial designers for prototyping.

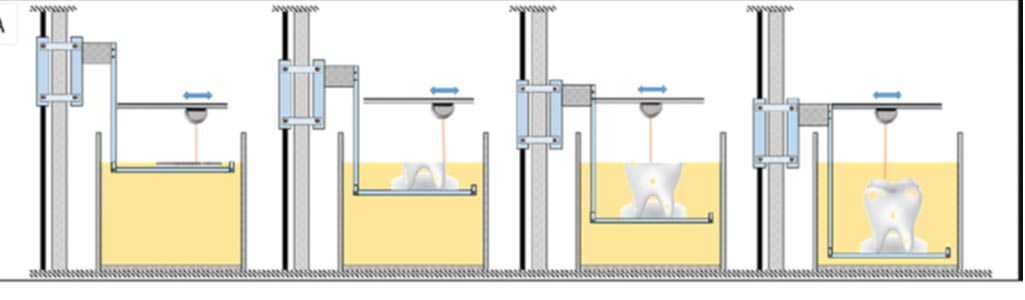

Stereolithography (SLA) :

In this printer, a tank containing liquid photopolymeric resin is used, and the desired object is created according to the virtual 3D model created by the CAD software. It is designed to be built layer by layer. Laser or ultraviolet light is used to harden each layer. This method is used in making crown and bridges, implant surgical guides and dental models.

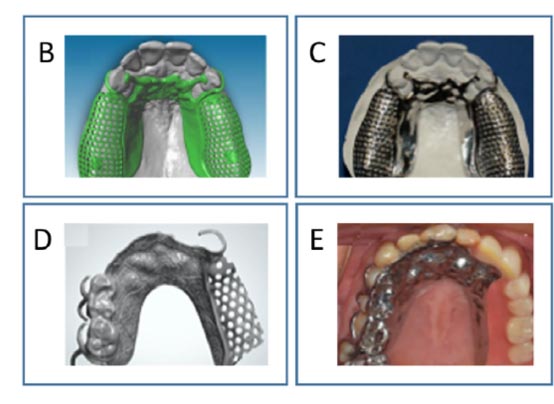

selective laser sintering (SLS) :

In this printer, a laser or electron beam is used to melt and fuse powdered materials and make a 3D object. The powdered materials used can be made of plastic, polymer or metal. This method is used to make metal components in dentistry, such as titanium implants and the metal frame of removable partial prosthesis, as well as to make ceramic crowns.